How To Make A Window Frame Out Of Wood

How to get together your Window.

Beneath is a guide to assembly of your kit grade window, if you require whatever further assistance please telephone call the states 01782 980468.

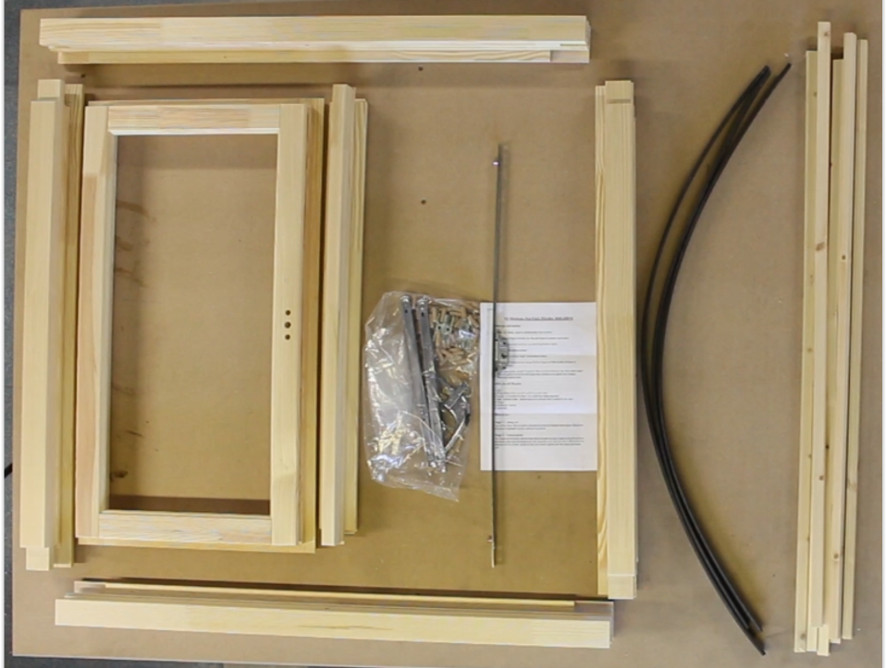

What you receive

- Head, Cill, Jambs, Transom / Mullion (Loose).

- Casements (Assembled ready to fit appertures)

- Glazing bead loose for cutting to length

- Casement gasket loose for cut to length

- Espagnolette multipoint locks with keeps & handles

- Friction Hinges

- Drinking glass sizes can exist provided if required

What yous will require

- Drill / driver

- Prophylactic Mallet

- Screws - 5.0 x 80mm for frame, 4.0 x 25mm for hinges and locks

- Glue - External Grade - delight ensure all glue surfaces are clean before associates

- Large clamp or strap

- Sandpaper / Sander

- Craft Knife

- Measuring tape (to check square)

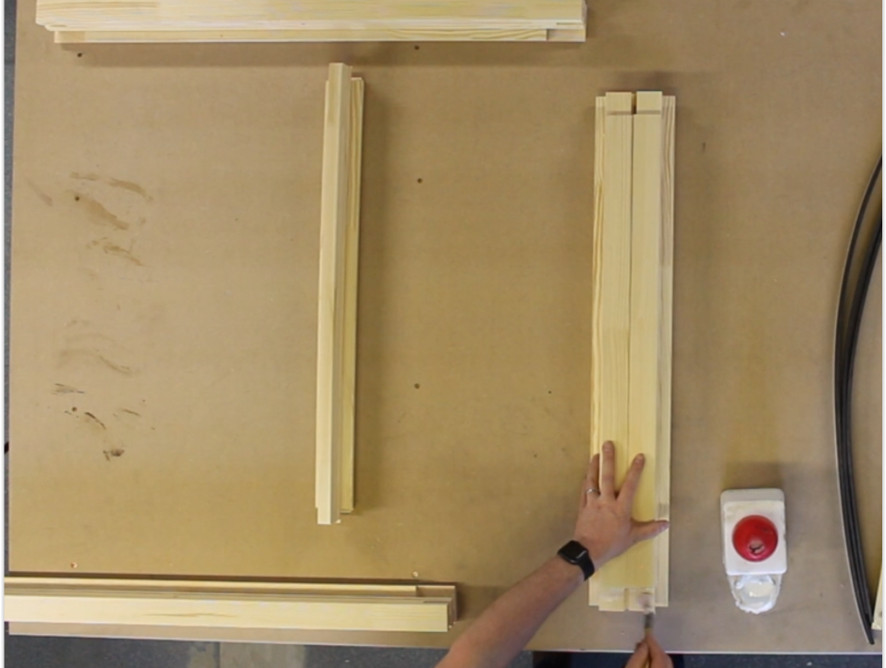

Step 1 - Setting out

Lay out The Caput, Cill and Jambs (dependent on style the transom and mullion) Ensure the cill groove if applicable is to the bottom of the window.

Stride 2 - Glue joints

You lot should now be happy with the frame layout and so grab your glue, apply to all joints (mortice and tenons forth with the dowels) and then slot the components together, your transoms and mullions are to be attached with the dowels, the jambs caput and cill slot together with the mortice and tenon joint.

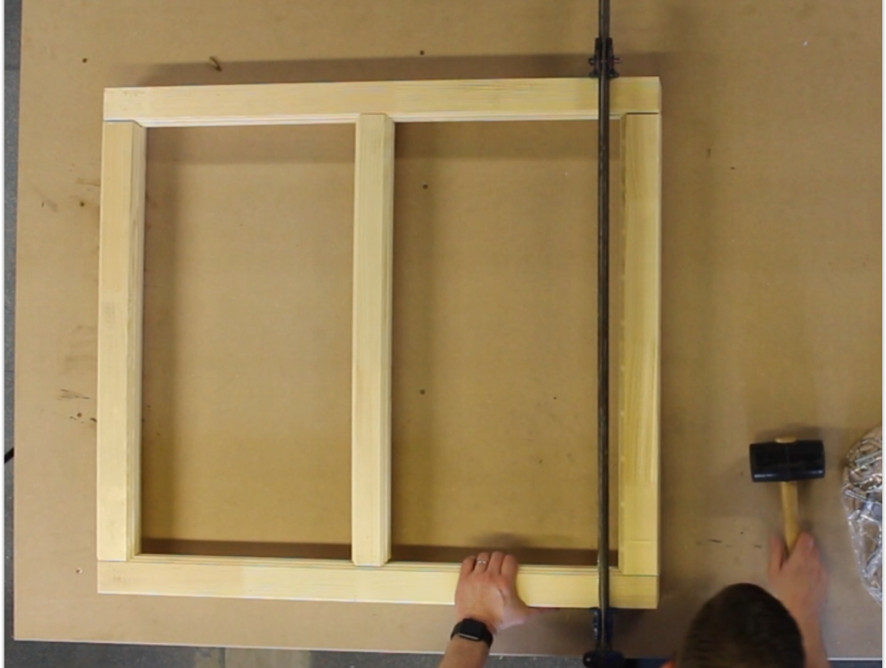

Pace 3 - Joints

To ensure all joints are tight and flush, tap them together using your mallet. Use a clench to close any tight joints.

Step 4 - Drilling & Fixing

Drill v.0mm pilot holes through the height of the head and the base of the cill for your jambs. Use your 5.0 x 80mm screws to secure the jambs in place.

Step 5 - Is it square?

Information technology is VERY Of import at this stage to Check that the frame is square by measuring corner to corner across both diagonals of the window (both diagonal measurements should be identical). Also, bank check the width and the height measurements.

Step 6 - Sanding the frame

Clear any excess glue from the frame using a damp cloth. Next, sand the window and casement until happy with the stop

Step 7 - Attaching cills and drip moulds (if applicable)

Clear whatever dust so apply Glue to the cill and drip mould so push into the grooves on the window face, for the cill to the base of the window and for the drip to the head of the window. Leave the glue to dry based on the glue manufacturer's recommendations.

Step eight - Fitting the casement gasket

Cut the gasket to length with your craft knife, y'all can line this upward with the gasket groove, install the gasket into the gasket groove starting with the pinnacle and lesser finishing with the sides.

Pace 9 - Fitting Locks

Fit handle, multipoint lock to casement with the 4.0 10 25mm screws.

Stride 10 - Plumbing fixtures Hinges

First fix the friction hinges to the casement - using a ruler to measure approximately 3mm from the rebate on the casement to the end of the flat on the hinge (before it starts to bevel at 45degreese). Fix the hinges using 4.0 ten 25mm screws. Next, with the hinges opened drop the casement into the frame. Slide the hinge upwards to the jamb and prepare in identify, again with 4.0 x 25mm screws.

Pace xi - Fitting Keeps

Position keep up to the small rebate, and in line with the locking machinery. Prepare into identify using 4.0 x 25mm screws. Cheque the operation of the casement and locking mechanism. Adapt hinge position if casement struggles to lock / unlock (the 3mm in step #ten).

Stride 12 - Glazing Beads

Mitre glazing beads to length.

Source: https://www.kitwindows.com/assembly-guide.html

Posted by: lopezprolent.blogspot.com

0 Response to "How To Make A Window Frame Out Of Wood"

Post a Comment